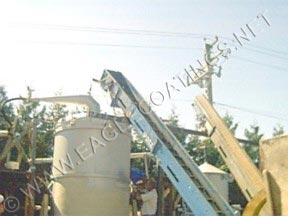

The tank was first coated with RUST GRIP ® to permanently stop the corrosion. Surface temperature readings were taken prior to the application of the HPC® COATING and registered at a steady state of 100°C / 212°F. The ambient temperature on 08/28/03 at 12:09PM was 30°C / 86°F.

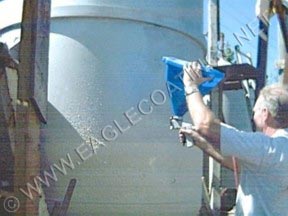

A primer coat of HPC® COATING was applied using a hopper gun and compressor at a thickness of approximately 50 mils (50/1000"). Initial surface temperature readings showed 70°C / 158°F. The temperature reduction will increase as the moisture evaporates. The Canadian Roofing Association testing shows that just 1 - 1 1/2% moisture content reduces the effective R value by at least 30%. Water is a conductor not a resistor.

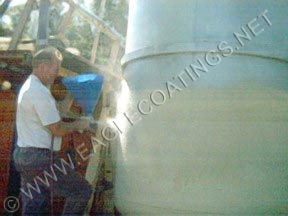

A build coat was then applied to approximately 100 mils and the surface temperature dropped to 42°C /104°F

A final build coat was applied before the SUPERTHERM ® \ ENAMOGRIP ® topcoats with a final thickness of 250 mils ( 250/1000" or 1/4 of an inch ). The final readings showed a surface temperature reduction from 100°C / 212°F to 24.7°C / 76.46°F.

The total coating system is comprised of :

~ RUST GRIP ® to eliminate any possibility of CUI ( corrosion under insulation )

~ HPC® COATING no mold, mildew, fungus or other biohazards growing in the insulation

~ SUPERTHERM ® no deterioration by weathering ( exterior application only ) for at least 10 years

~ ENAMOGRIP ® on the front only to protect the SUPERTHERM ® where the boiling hot water is poured out.